The egg carton making machine allows you to make all of the egg cartons you need for a cheap price. This machine is affordable and it is efficient. It ensures you can make all of the egg trays you need and you won’t have to spend a lot of money to make the trays either since the machine is so efficient.

Paper Egg Carton

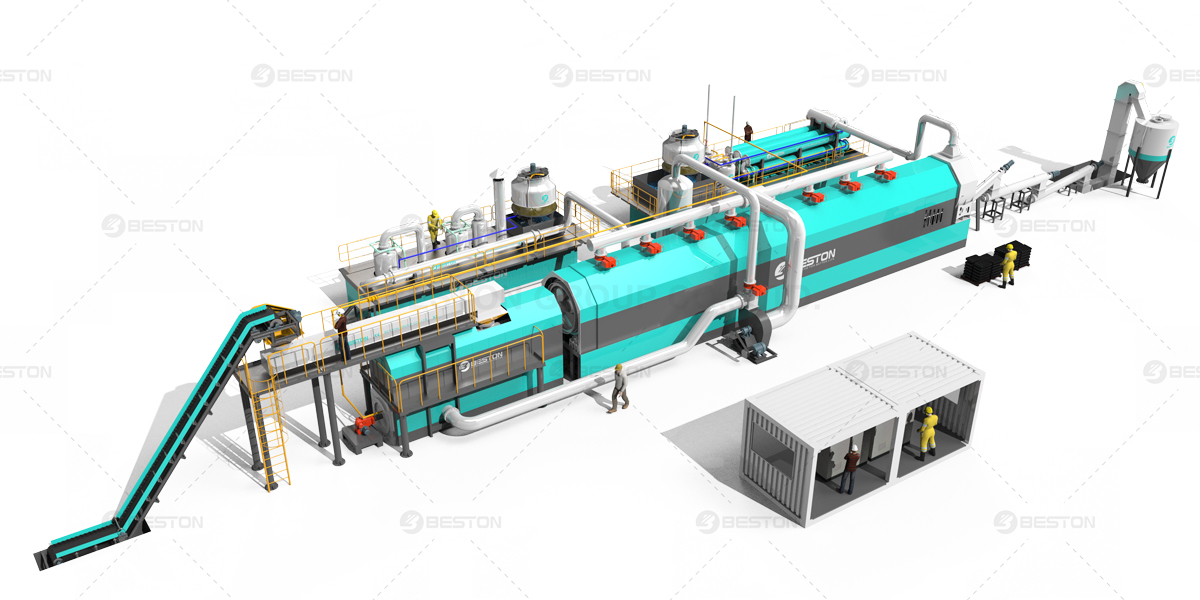

This machine is very versatile and it can make a variety of trays like fruit trays and shoe trays. All you have to do is buy the right mold and you can make all of the different trays that you need. The machine produces high-quality trays that are strong and durable and will protect all of your eggs.

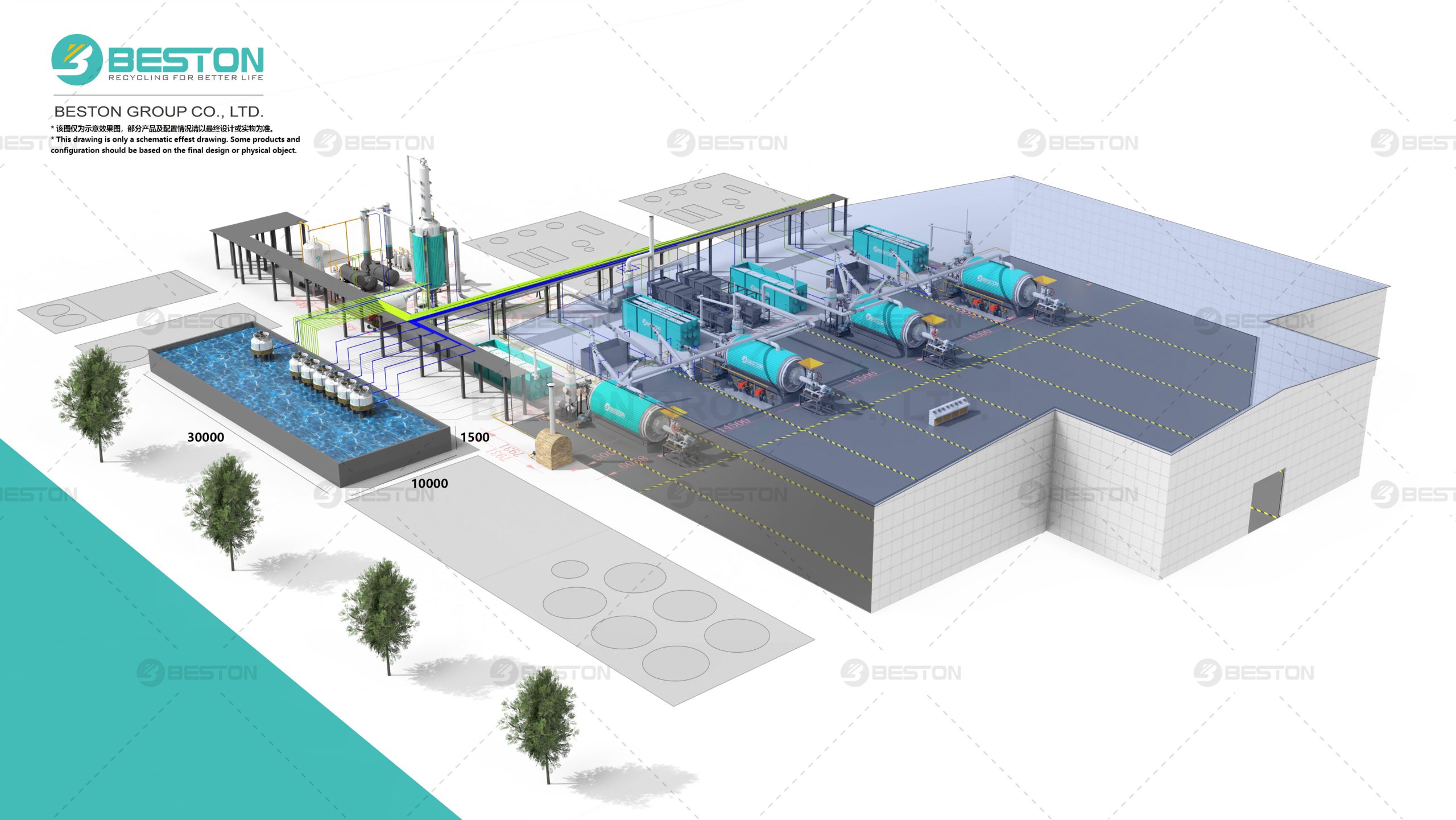

The egg carton machine for sale is often found on chicken farms for farmers who want a finished product that is ready to be shipped to the grocery stores. Other businesses can produce the trays too and sell them directly to businesses and farms. Businesses can make a great profit with this machine and the affordable price ensures you can make your money back quickly with it.

Affordable Egg Carton Making Machine for Sale

One of the great things about this machine is that it takes waste materials to make the trays out of which keeps the price down so low. You can use all kinds of waste paper to produce the trays. Waste books, newspapers, boxes and more can all be used to make the trays and this makes it very affordable.

The machine is good for the environment since it recycles waste paper and the paper egg box making machine is also designed to use low amounts of energy. They won’t use a lot of power and each machine features anti-dust technology that ensures that the machines don’t produce dust. The way the machine works is very simple. The machine takes the waste paper and adds water to it in the pulping chamber. In the pulping chamber the paper is pounded with the water until it is turned into a fine pulp.

The price of the machine will depend on the model that you buy. The manual machine is the least expensive. The automatic machine is the most expensive. You will have to think about what your needs are when you are choosing the machine so you invest in the best one. The machine will produce thousands of top quality egg trays each hour so you need to buy the machine that is the best fit for your business. A paper egg tray machine gives you an affordable way to produce lots of egg trays. The machine can help your business thrive and make it easier to make money.